"First Time Right" is the mantra for MMF’s engineering team. New Product Development is pursued by using Advanced Product Quality Planning (APQP) techniques, with the involvement of the cross function team. This brings in the collective wisdom of our core team, process knowledge and is complimented by the use of cutting edge technologies.

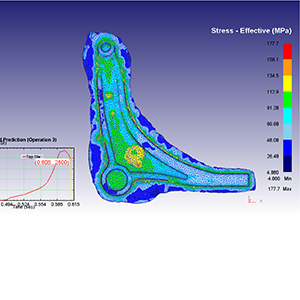

MMF uses advanced world class 2D and 3D software’s for tool design. Process drawings are made seamlessly and 3D modeling is used for further processing.MMF uses advanced design validation software’s for pre form design analysis and Finite element analysis [FEA] software’s for tool design optimization and input material optimization.

Continuous improvement is the major growth driver for MMF. FEA tools are used for increase in die life by input material weight reduction, Tool stress analysis, Tool wear analysis, Temperature distribution, Usage of alternate tool steels, grain flow analysis etc. Advanced 3D scanners with our engineering team helps to study actual wear out of the tools and impact on the life of the tool and compare with the FEA results.

New Product Development is the core to the growth of MMF and focus on New Product Development by Failure Mode and Effect Analysis, and structured problem solving approach helped us achieve record breaking turnaround times. By focusing on the core principles and excellence in engineering, the foundation is stone is laid for “Forging excellence”